digital

twin

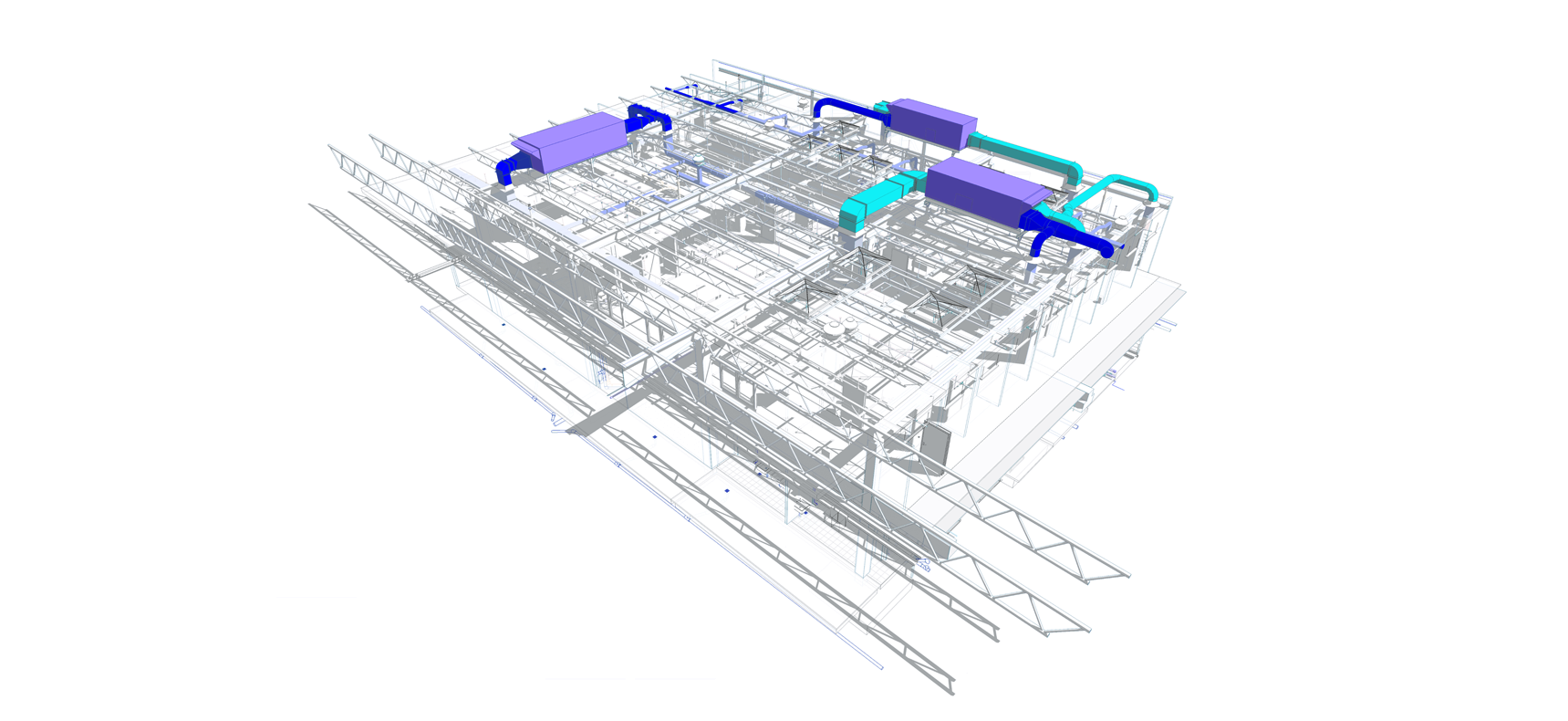

The digital twin service is aimed at customers, who want to fully use the potential of BIM and information contained in 3D building models, in particular, at the facility operation stage. We provide our clients with complex support during information modeling process, in particular:

- development of a three-dimensional model based on a 2D drawing with an agreed level of detail

- updating the model and introducing design changes during the investment

- cyclical updating of model information, such as built-in devices or material solutions used during construction works,

- handing over the database and model to the facility manager or owner after project completion.

The end result of building digital presentation is a model with information included in the as-built documentation. By appropriately combining elements in the model space with documents in .pdf, .doc or .jpg files, building owners or facility managers can easily access relevant information during the operation of the building.

If we could get ahead of future events...

Digital Twin is a powerful spatial data set, which allows to simulate future plans and possible scenarios. We can check different types of scenarios and get an answer to the question “what if?”. Such a digital simulation can be performed on many different levels – the financial level, the overall business strategy, or even the organizational structure. Because this type of analysis is performed in a virtual environment, as opposed to the risk-bearing real environment, the cost of obtaining data and information resulting from the creation of a digital twin is relatively low. For this reason, the creation of a digital twin is conducive to checking ideas, prototyping, verification of business decisions, which in turn leads to continuous business innovations according to the Plan-Do-Check-Act.

BIM up

your design

Process

BIM up

your design

Process

Digital Twin is a concept that is becoming more and more entrenched among people operating in the construction industry. Digital twin is a virtual model of the object enriched with a number of information supplemented during the project delivery. Each stakeholder can contribute to the construction of the digital twin and can benefit from it at any stage of the project. During the design and project planning, the digital twin allows stakeholders to better understand the designer’s assumptions and prepare for the realization of the object. The transformation of flat documentation into a 3D model and integration with spatial location data allow investors to correctly interpret and verify the designers’ assumptions.

The undoubted benefit for the contractor is the ability to optimize the site works schedule, planning logistic elements such as access roads, material storage places, etc. Digital twin “lives” in parallel with the construction of a real object. After the building is handover to use, the end user can monitor the facility, starting from technical condition control, through media consumption management, ending on economic building maintenance analysis. Thus, the construction and use of the digital twin takes place on the basis of communication and data exchange between all parties of the project.

Currently, thanks to the development of virtual reality technology, after all as-build information are implemented to the model, it is possible to view elements of the building, which are invisible to the user e.g., installation in the space above suspended ceiling, inside installation shafts, hard-to-reach places. Selected elements are virtually displayed on the screen, taking into account the user’s location inside the facility. Such advanced technology allows for quickly determination the root cause of a defect and thanks to additional information about faulty element, it is possible to contact with technical support or service without undue delay. The development of the digital twin technology is not only the result of a fascination with virtual reality, primarily it is a tool for facility management team and people related to facility maintenance.

It is often the case that a project requires the involvement of more advanced technological solutions from the very beginning in order to start developing the model and project documentation. Such a situation takes place during works related to the modernization or reconstruction of existing facilities and historic projects. Then the first element of the digital twin is a credible representation of the existing structure in three-dimensional space. Currently, the most popular solution on the market is laser scanning. 3D laser scanning automatically collects point data even from a distance of 300m, while achieving precision up to 1mm. This allows for an accurate mapping of the actual dimensions of building elements, damage to structural elements and exact survey of pipes or cabling. Laser measurements are delivered in the form of a point cloud, which is then processed in the native environment and developed as a model. Considering how time-consuming and imprecise traditional inventory methods could be, the use of laser scanning technology starting works on digital twin seems a reasonable solution.

BIM

FOR DESIGNERS

Designer Support

clash

detection

Clash Detection

3D

quantity takeoff

3D Quantity Takeoff

BIM 4D

project management

4D BIM Schedule

digital

twin

Digital Twin

BIM for manufacturers

w REVIT

BIM for manufacturers